RIGGING SCREW FORK/TERMINAL METRIC

• Email: [email protected]

• Direct: 07 5535 5055

High Polished Stainless Steel – AISI 316

The price favourable and durable Stainless Steel Rigging Screw line from Blue Wave has been a favourite among Riggers and yachtsmen for the last 50 years. It offers a variety of features. Laser engraved thread size, Blue Wave logo, and side marking of the left thread.

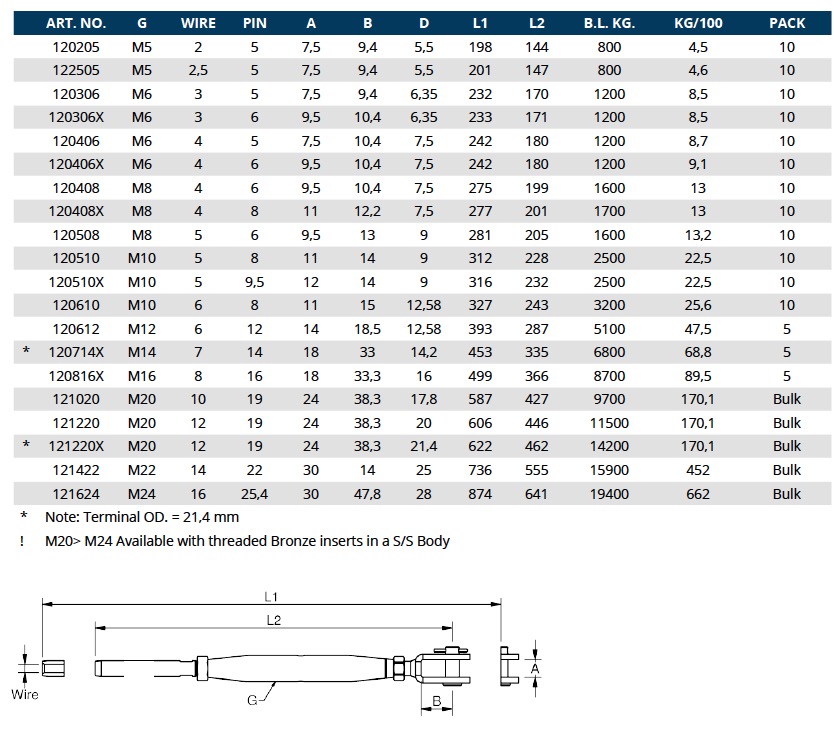

All AISI 316L/A4 Material – BL tested and features; laser engraved thread size, LH thread side marking. Turnbuckles with terminals show wire size and outside wire hole depth marking for easy handling. Supplied with streamline Blue Wave locknuts.

Description

The price favourable and durable stainless steel metric rigging screw fork range from Blue Wave has been a favourite among Riggers and yachtsmen for the last 50 years. It offers a variety of features. The metric rigging screw forks have laser engraved thread size, Blue Wave logo, and side marking of the left thread. The rigging screw fork are made from AISI 316 grade stainless steel.

Replacement Split Pin (Cotter Pin) and G Ring (Split Ring) are also available online.

Blue Wave is also now a ISO9001 Certified Company, a worldwide recognition of quality management systems standards. This certification certifies Blue Wave’s commitment to meeting the needs of customers and other stakeholders while meeting statutory and regulatory requirements related to our product and service.

Blue Wave hardware is distributed throughout Australia and New Zealand by ProRig Hardware. For information on the Blue Wave product range download our catalogues for Wire Design Systems, Rope Line and Marine by visiting our Catalogue page.

Please see our range of stainless steel hardware via the links below.

Rig Maintenance

All rigs should be checked and maintained regularly. The rig and sails are your boat’s “engine” and as with all engines, the fittings should be checked at least twice a year. Are your rigging screws starting to fail? Are all treads and pins intact? Cleaning the fittings and adding fresh lubricant, will extend the lifetime of your rig. A rig’s lifetime depends upon the standard of maintenance, however as a general rule, your boat needs to be de-rigged and inspected, at least every other year. A qualified inspector should inspect a wire rig after 10-15 years and a rod rig after 5-8 years.